GRP Water Tanks / FRP Water Tanks

GRP (Glassfibre Reinforced Polyester) Water Tanks | GRP Panel Water Tank Installation

Traditionally, water storage tanks for residential, commercial, industrial and government projects has been constructed using reinforced cement concrete (“RCC”). While use of RCC for water storage tanks has been in use for decades, there are certain inherent drawbacks of RCC tanks which are not suited to modern construction projects. Chronic leakages, time consuming construction period, heavy weight, inflexibility, higher maintenance and poor water quality of RCC tanks are common pain areas for projects utilising RCC tanks.

Technologically advanced Glassfibre Reinforced Polyester (GRP) Water tanks which are made of panels made of composite material using sheet molding compound (SMC) address many of the challenges of RCC tanks, and are designed as a long term replacement to RCC tanks. Due to the use of SMC manufacturing process, GRP tanks are also often referred to as ‘SMC panel water tanks’. It is important to note that only the ‘hot press’ method of forming GRP tank panels under high temperature and pressure provides the strength and durability to GRP panels.

They offer many advantages:

- Leak free

- Rapid construction (installation) using modular design

- Very lightweight

- Flexible in shape and size, and can be dismantled/modified after GRP tank installation

- Maintains excellent water quality throughout the life of the tank

- Can be easily installed in difficult sites with limited access/height restrictions

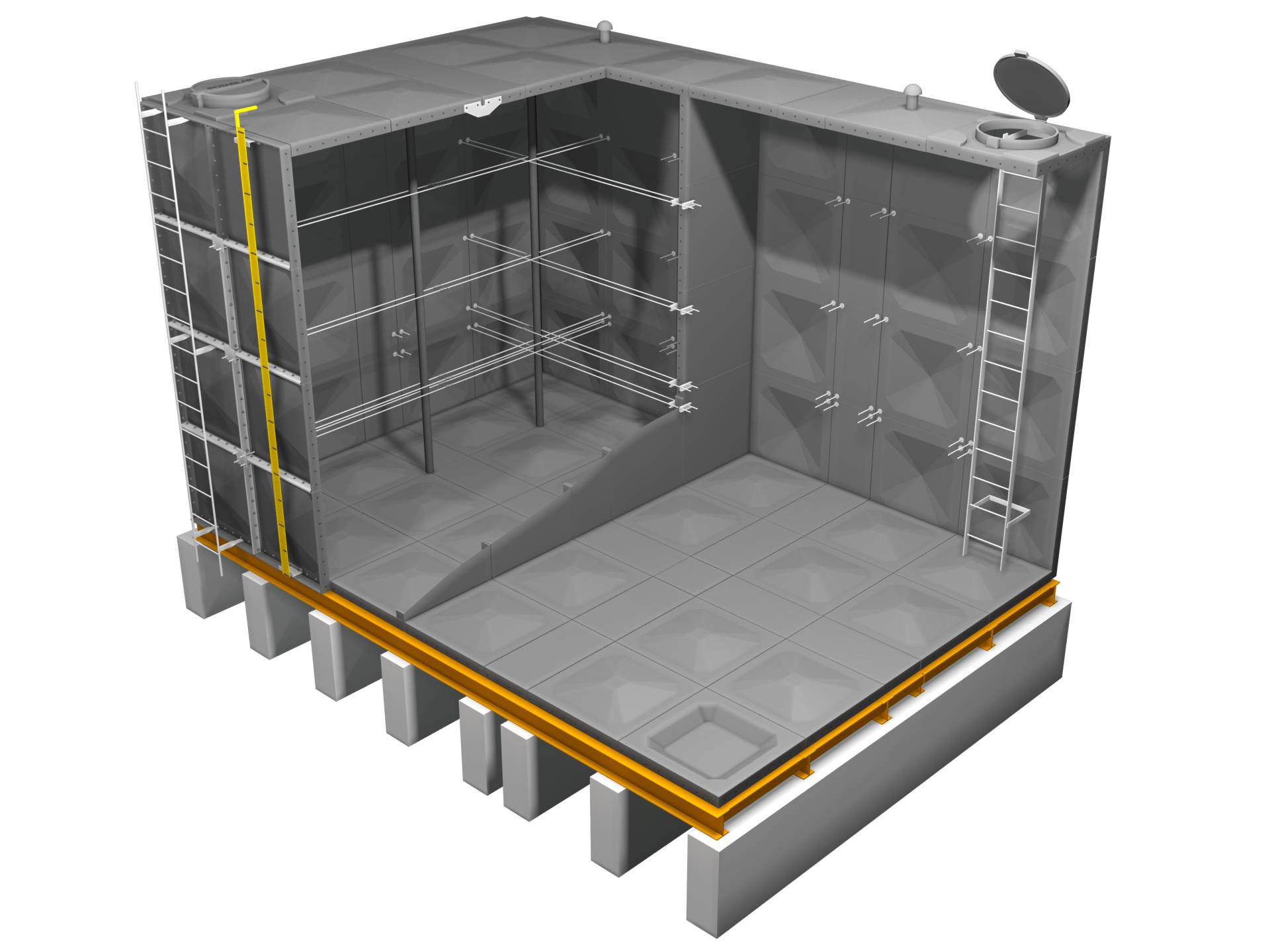

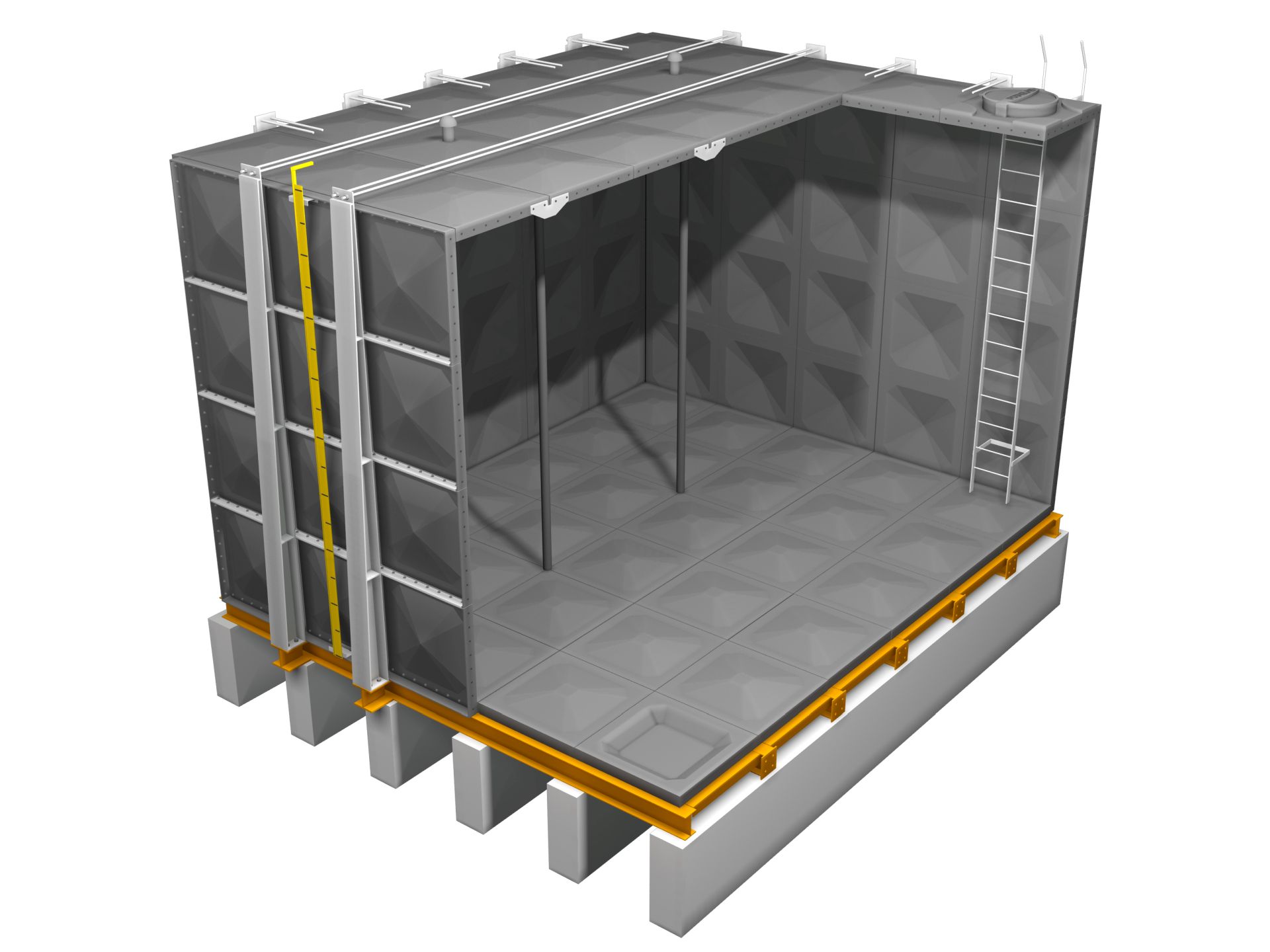

Typical GRP tank, showing internal and optional external reinforcement

India is not a water scarce country and ranks among the top ten water rich countries in the world according to data from World Resources 2000-2001 (World Resources Institute, 2000).

However clean drinking water is a scarce commodity in India.

The safe & leak proof storage of clean potable water for drinking & industrial use is of utmost importance as it is a scarce commodity.

For clean water storage concrete and steel sectional tanks have been widely used in applications such as Municipal water supply, housing complexes, buildings, hospitals, rural water supply, industries, and other facilities. The use of concrete and steel, however, has their own certain inherent disadvantages.

| Industrial | Residential | Muncipal | Specialised |

|---|---|---|---|

|

|

|

|

| Large Capacity | Water Quality | Large Capacity | Large Capacity |

| Fast Deployment | Long Life | May be Elevated | Fast Deployment |

| Low Maintenance | Low Maintenance | Low Maintenance | Water Quality |

| Light weight | Fast Construction | ||

| Partition | Long Life | ||

| Shape Flexibility | Easy to Repair |

For clean water storage concrete tanks have been widely used in applications such as Municipal water supply, housing complexes, buildings, hospitals, rural water supply, industries, and other facilities. The use of concrete and steel, however, has their own advantages and disadvantages.

| Advantages | Disadvantages |

|---|---|

| Long Life | Water Quality Deteriorates Over Time |

| Readily Available Materials | Variable Construction Quality |

| Tried and Tested | Long Time Taken For Construction |

| Cost Effective | Cracks Once Appears Difficult For Permanent Rectification |

| Flexible in Shape With Good Engineering | Heavy Weight |

| High Maintenance, scrubbing |

| FTC GRP / FRP Panel water tanks | RCC water tanks |

|---|---|

| No service failures reported in 40+ years.

Hot pressed sheet mould compound (SMC) with a temperature of 150° C and pressed with 50 Kg pressure per cm² is used to produce a uniform panel of solid homogenous construction. Average serviceable life for panels in normal conditions without maintenance is ± 40 years. Tested for heavy impact, weather, loads, settling and earth quakes. Safety factor of 6 x above maximum anticipated load. Excellent ultra violet (UV) resistant characteristics and performance. Option of pre-insulated panels to lower the thermal conductivity at both the high and low temperature level |

Durable when no settlement or cracking occurs.

Concrete is highly absorbent of water. Heat and humidity above variable water levels in a closed tank increase absorption reaching the reinforced steel bars causing corrosion that leads to expansion and ultimately cracking of the concrete. Concrete has high thermal conductivity, which in cold weather freezes water and results in cracking. |

Water Quality

| GRP Tanks | RCC Tanks |

|---|---|

| Smooth mirror surface of the panel prevent dirt adhesion and bacterial growth.

Light proof to prevent algae growth. Light transmittance for panels including manhole cover is 0,00%. The hot pressing method for panels eliminates styrene and makes it an ideal product for storing drinking water. Tanks are completely sealed, manhole covers and air vents are by design dust and insect proof. No metal components need to be in contact with water. Reinforcement, bolts and nuts for assembly are on the outside. Exclusive base panel design ensures complete free flow drainage; this eliminates residual contaminated water with cleaning. |

Rough surface collects dirt and bacteria.

Light penetration from manhole results in algae growth. Manhole gaps and corridors encourage breeding of insects and accumulation of dust. Base line cracks result in water contamination. Flat bottom will not allow complete drainage of hose pressure water with chemicals resulting in contamination of incoming water.

Chlorine causes degradation of the tank surface that provides room for bacteria growth. |

Leakage

| GRP Tanks | RCC Tanks |

|---|---|

| Exclusive design of convex bottom panels with flexible rubber sealant is most effective against risk of leakage.

Modular panel with low thermal coefficient and flexible rubber sealant ensures a leak free design. Accessible from all sides including bottom for easy visual inspection. |

Settlement and cracking results in leakage.

Base line leakage is difficult to detect resulting in serious damage and collapse of the tank. Poorly sealed and maintained tanks will absorb water, which will corrode the steel reinforcement inside concrete causing cracks due to expansion and leakage. Freezing causes cracking that will result in leaks. |

Physical Properties

| GRP Tanks | RCC Tanks |

|---|---|

| Exceptional panel strength in compression, tension, torsion (Rigidity)

Panels individually designed for optimal performance with a safety factor of 6. Designed and tested to withstand at least 40 years anticipated natural conditions in Japan. Long life UV protection. Low thermal conductivity. |

Low seismic tolerances.

Long life expectancy in absence of cracks. Flexible in Design. Longer life in temperate weather conditions. High thermal conductivity. Quality of the concrete is very hard to control at site and depends on the workmanship. |

Tank Weight

| GRP Tank | RCC Tanks |

|---|---|

| Less than 1/10th of RCC tanks.

Hence weight of support columns & beams reduces proportionately. |

At least 10 times more than GRP tanks

Hence weight of support columns & beams increases proportionately. |

Repair And Maintenance

| GRP Tanks | RCC Tanks |

|---|---|

| Repair and maintenance can be done externally without interrupting supply.

Irreparable accidental damage will be solved by replacing damaged panel, with basic hand tools. Partition inside tank allows continuous water supply during maintenance. Maintenance limited to outside bolt tightening/ and internal hose water pressure wash down without chemicals. Complete water drainage by design. |

Causes interruption of water supply.

Steel reinforcement is subject to corrosion and deterioration from water contact due to cracks. Rough and uneven surfaces require hose water pressure for wash down with chemicals to kill bacteria and clean dirty surfaces. Flat bottom will not allow complete drainage of hose pressure water with chemical, resulting in contamination of incoming water. Costly to maintain. Repair is only a temporary solution to leakage problems. |

Adaptability Of Size And Design

| GRP Tanks | RCC Tanks |

|---|---|

| Flexible sizes and shapes by design could range from 10 m³ to 10,000 m³.

Can easily be extended at any time as storage requirement increase. Can be relocated easily from one location to another several times. Limited to 4.0 Meter in height |

Flexible in size and shape.

Unable to increase size or volume. Not relocatable. |

Handling And Assembly

| GRP Tanks | RCC Tanks |

|---|---|

| Minimum assembly equipment requirement, using basic hand tools.

Panel is lightweight and easy to handle. Uniform quality end product. Minimum volume and lightweight to transport, e.g. Pallet 2m³ = 400 kg to build a tank of 9 m³, transport volumes decrease proportionately per m³ as tank volumes increase in size. |

Long time and skill level of labour and equipment needed to complete tank construction.

Building tanks in urban areas involves construction requiring the transportation of large quantities of materials, equipment and manpower. Building tanks in remote areas require special utilities that are not always readily available as well as the requirements related to regular urban construction sites |

Insulation Properties & Characteristics

| GRP Tanks | RCC Tanks |

|---|---|

| Insulated panel option available for extreme weather conditions (hot or cold).

Excellent for industrial purposes where chilled water is required in volume. Non-insulated Panels have 240 times less thermal conductivity than metal, ensuring stable temperatures. |

Acceptable thermal properties in temperate weather conditions |

Corrosion Properties

| GRP Tanks | RCC Tanks |

|---|---|

| Not applicable (No steel in direct contact with water). | Water absorption in poorly or untreated concrete tanks is high causing corrosion to the internal steel reinforcement that in turn causes expansion cracks to

the concrete. |

Trusted Partners

Our Satisfied Clientele

Get A Quote Today

Please fill the below details and our representative will get back to you.